Telephone:0534-2350883

Fax:0534-2350883

Phone:18233233061

Address:South Outer Ring Road, Decheng Economic Development Zone, Dezhou City, Shandong Province

KY41 series vertical parting boxless injection pressure automatic molding line performance characteristics:

● High productivity, high casting size precision, low noise, low labor intensity, simple assembly line, few auxiliary machines, small area, low process and construction investment, energy saving, is the most advanced and efficient tidal mold sand molding line.

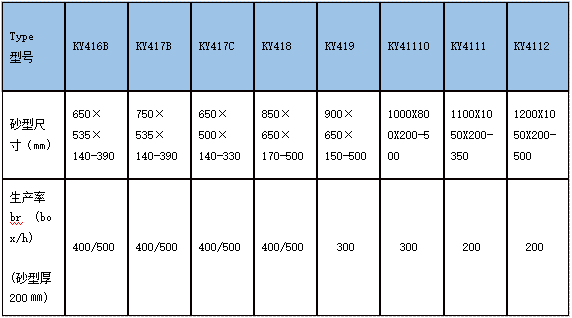

Technical parameters of ky41 series vertical parting automatic molding line without box injection pressure

The main components of the molding line : the molding line is mainly composed of a molding host, a sand adding machine, a translational core core machine, a synchronous clamping conveyor, a belt cooler, a sand falling machine, and electronic control, hydraulic pressure, and air control systems. The molding machine adopts the compaction method of sand shooting and hydraulic compaction to realize the sand molding, and at the same time complete the work of lifting, closing and pushing. The sand adding machine completes timing and quantitative sand adding to the host machine. The translation-type core-driving machine realizes fast and accurate online synchronous core -loading , which is an optional item.

Template replacement: set air lock to automatically replace the template. The synchronous clamping / supporting conveyor and the host machine complete the pouring, casting and cooling synchronously. Available in lengths of 12M and 18M . According to the cooling time of the casting, the synchronous belt cooler extends the cooling time of the casting after synchronously clamping the conveyor to prevent the deformation of the casting.

The pouring department can be equipped with a pouring machine to complete automatic pouring, or a ring rail hanging bag supplemented by manual pouring.