Telephone:0534-2350883

Fax:0534-2350883

Phone:18233233061

Address:South Outer Ring Road, Decheng Economic Development Zone, Dezhou City, Shandong Province

The static pressure automatic molding line adopts blown pre-compacting and multi-contact high-pressure compaction molding technology. The sand mold has high hardness, uniform tightness, high boxing accuracy, high casting accuracy and high yield. The average hardness of the sand mold is 90-95, the hardness difference on the same surface is ﹤ ± 5, and the amount of wrong mold is ﹤ 0.3㎜. Hydraulic multi-contact compaction, proportional pressure reducing valve pressure regulation, compaction specific pressure zone adjustable, up to 1.5Mpa. The control system is equipped with an engineer station, an operation master station and multiple machine-side slave stations, each equipped with a man-machine interface, using industrial computer, numerical control, PLC field bus, servo technology, proportional valve, frequency control, automatic detection, computer monitoring advanced technology. The action of the whole line adopts the principle of combining electrical, hydraulic and pneumatic transmission, and the key components are imported products to ensure the smooth and reliable operation of the production line. It has the advantages of full automatic, high productivity, high casting precision, small footprint and low energy consumption. It is the most advanced molding production line at present. It is suitable for the production of large quantities of high-end parts, and has been widely used in the production of automobile castings and other gray iron, ductile iron, and steel castings.

Technical parameters of static pressure automatic molding line:

Type model |

Sand mold size (mm) |

Productivity (box / h) |

Amount of molding sand (t / h) |

KY807 |

800 × 700 × 220/220 |

150 |

60 |

KY108 |

1000 × 800 × 300/300 |

110 |

85 |

KY129 |

1200 × 900 × 350/300 |

100 |

115 |

KY139 |

1300 × 900 × 350/350 |

90 |

120 |

KY1510 |

1500 × 1000 × 400/400 |

80 |

155 |

KY189 |

1850 × 900 × 350/350 |

60 |

130 |

KY2015 |

2000 × 1500 × 550/450 |

30 |

145 |

KY2512 |

2500 × 1200 × 550/450 |

30 |

145 |

The main part of the molding line : the molding line is mainly composed of five sections : molding, lower core combination box, pouring, cooling and falling sand. Including static pressure molding host, a full set of auxiliary machines, casting conveyor, electronically controlled hydraulic system, sand box, mold plate and other technological equipment. Static pressure molding machine: mainly including lifting table, air blowing pre-compacting device, multi-contact compaction device, louver type sand adding device, template rotation device and upper frame moving device, etc., to complete quantitative sand adding and molding , Molding and template conversion process. Auxiliary machine for molding line: mainly poke box machine, sub-box, lifting box, drop box, box transfer machine, box turnover machine, sweeper, box closing machine, tight box and loose box device, air hole drilling device, milling gate device Wait, complete the auxiliary process across the board. Casting conveyor: there are mainly transfer vehicles, transmission push rods, buffer push rods, trolleys and positioning devices, etc., which are used for automatic transfer of molds. Control system: equipped with engineer station, operation master station and multiple machine-side slave stations, equipped with man-machine interface, using industrial control computer, numerical control, PLC field bus, servo, proportional valve, frequency conversion speed regulation, automatic detection, computer monitoring and other advanced Technology, key components are imported products. Pouring system: It can be completed by automatic (semi-automatic) pouring machine. Ventilation and dust removal system: mainly used for ventilation and dust removal in the pouring section and cooling section.

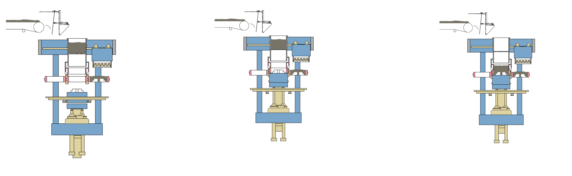

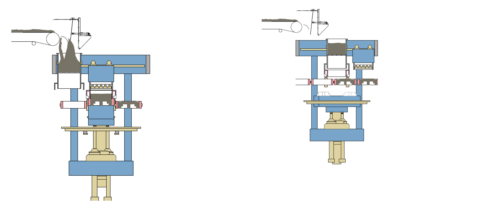

Process of static pressure molding machine

1. In and out of the box, template replacement 2. Ascending the box 3. Sand

4. Move multi-contacts, press tightly, blow, compact